Global Fiber Laser Market to Reach USD 15.1 Billion by 2036 as Precision Manufacturing Accelerates Worldwide

Automation-Driven Manufacturing Expansion and High-Power Laser Integration Propel Double-Digit Growth Through 2036

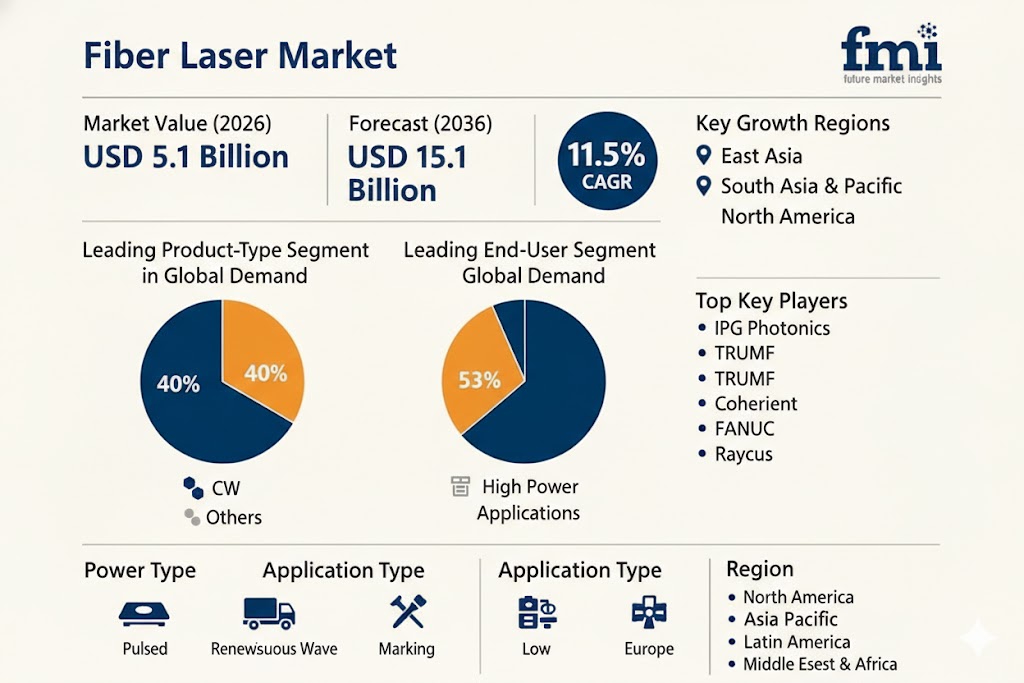

NEWARK, DE / ACCESS Newswire / February 11, 2026 / The global manufacturing sector is entering a new era of ultra-precision, automation, and energy-efficient processing. At the center of this transformation is the Fiber Laser Market, valued at USD 5.1 billion in 2026 and projected to surge to USD 15.1 billion by 2036, expanding at a robust CAGR of 11.5%.

According to the latest industry analysis, rising adoption of automated production lines, demand for high-speed cutting systems, and increasing investment in advanced manufacturing technologies are driving fiber laser integration across industrial ecosystems.

Precision Meets Productivity: Why Fiber Lasers Are Gaining Momentum

Fiber lasers have become the backbone of modern industrial processing due to their superior beam quality, energy efficiency, and operational reliability. Unlike traditional CO2 or solid-state lasers, fiber lasers offer:

Higher electrical-to-optical efficiency

Reduced maintenance requirements

Compact system design

Enhanced cutting accuracy

Manufacturers across automotive, aerospace, electronics, and heavy machinery sectors are deploying fiber laser systems to reduce operational costs while achieving micron-level precision.

Market Snapshot (2026-2036)

Metric | Details |

|---|---|

Market Value (2026) | USD 5.1 Billion |

Forecast Value (2036) | USD 15.1 Billion |

Projected CAGR | 11.5% |

Leading Laser Type | CW (76.1% Share) |

Leading Output Power | High Power (62.7% Share) |

Top Application Segment | Cutting (44.2% Share) |

Key Growth Regions | East Asia, South Asia & Pacific, North America |

CW Dominance: Continuous Wave Leads the Charge

By laser type, Continuous Wave (CW) systems account for 76.1% of global demand, making them the leading segment.

CW fiber lasers are preferred for:

Superior power efficiency

Stable beam quality

Continuous high-speed cutting

Heavy-duty industrial processing

While pulsed and QCW lasers maintain relevance in microprocessing and specialty applications, CW platforms remain the industry standard for large-scale manufacturing operations.

High Power Applications Command the Largest Share

By output power, high power fiber lasers dominate with 62.7% market share.

Their applications include:

Thick metal cutting

Heavy-duty structural fabrication

High-speed industrial processing

Automotive body manufacturing

Medium power systems serve balanced manufacturing needs, while low power lasers are utilized in precision marking and fine microprocessing applications.

Cutting Applications Drive Core Demand

Among applications, cutting holds the largest share at 44.2% globally.

Fiber laser cutting supports:

Automated sheet metal processing

Precision component fabrication

Industrial production line optimization

Advanced material processing

Welding and high-power applications follow closely, especially in heavy manufacturing sectors requiring structural assembly and thermal precision. Marking applications support traceability and quality control across electronics and automotive industries.

Regional Growth Dynamics: Asia Leads the Acceleration

While demand is global, adoption patterns vary significantly across regions.

India - 16.8% CAGR

India emerges as the fastest-growing market, driven by:

Expanding manufacturing infrastructure

Government-backed industrial modernization

Rising automation adoption

Increased deployment of precision cutting systems

China - 15.2% CAGR

China continues rapid expansion due to:

Large-scale industrial automation

High-volume production capacity

Competitive laser system pricing

Strong domestic manufacturing demand

United States - 12.9% CAGR

The U.S. market grows steadily, supported by:

Advanced automotive manufacturing

Aerospace innovation

Strict quality standards

Investment in automation and robotics

Germany - 11.7% CAGR

Germany's precision engineering ecosystem drives:

Premium laser adoption

Industrial research collaboration

High-standard production frameworks

Japan - 10.5% CAGR

Japan's demand is anchored in:

Advanced electronics manufacturing

Precision engineering expertise

Government-backed industrial technology programs

Key Market Drivers

Several macroeconomic and technological trends are fueling fiber laser adoption:

Rising demand for precision manufacturing

Integration of AI-driven automation systems

Increased focus on production efficiency

Growing automotive and EV production

Expansion of smart factories

Manufacturers increasingly integrate fiber lasers with automated control systems and real-time performance monitoring to enhance operational accuracy and reduce downtime.

Navigating Challenges: Cost, Regulation, and Infrastructure

Despite strong growth, certain factors influence scalability:

High capital investment requirements

Safety and regulatory compliance standards

Technology compatibility with legacy systems

Infrastructure adaptation costs

Cost-sensitive markets must balance upfront investment against long-term productivity gains. However, declining system costs and improved energy efficiency are steadily improving ROI calculations.

Competitive Landscape: Innovation at the Core

The fiber laser market remains highly competitive, with major players investing in performance optimization and scalable production platforms.

Leading Global Players:

IPG Photonics Corporation

TRUMPF GmbH + Co. KG

Coherent Inc.

FANUC Corporation

Wuhan Raycus Fiber Laser Technologies

Furukawa Electric

Newport Corporation

Keopsys SA

Fujikura Ltd.

Lumentum Operations LLC

These companies compete through:

Advanced beam control technologies

Automation-ready laser platforms

High-efficiency manufacturing systems

Global distribution networks

Scalable industrial solutions

IPG Photonics and TRUMPF remain technology leaders, while Raycus continues expanding cost-effective industrial laser adoption in Asia.

Outlook to 2036: From Advanced Tool to Industrial Standard

By 2036, fiber lasers are expected to transition from specialized industrial equipment to standard infrastructure within smart manufacturing facilities.

As automation, robotics, and AI-driven production systems become mainstream, fiber lasers will serve as the precision engine powering:

Automated material processing

High-speed fabrication

Quality assurance integration

Energy-efficient industrial production

With global manufacturing modernization accelerating, the fiber laser market is positioned not just for expansion-but for structural importance within the next generation of industrial transformation.

For an in-depth analysis of evolving formulation trends and to access the complete strategic outlook for the Fiber Laser Market through 2036, Full Report Request: https://www.futuremarketinsights.com/reports/fiber-laser-market

Related Reports:

Laser Vibrometer Market- https://www.futuremarketinsights.com/reports/laser-vibrometer-market

Fiberglass Centrifugal Fan Market- https://www.futuremarketinsights.com/reports/fiberglass-centrifugal-fan-market

Laser Component Analyzer Market- https://www.futuremarketinsights.com/reports/laser-component-analyzer-market

About Future Market Insights (FMI)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. Headquartered in Delaware, USA, with a global delivery center in India and offices in the UK and UAE, FMI delivers actionable insights to businesses across industries including automotive, technology, consumer products, manufacturing, energy, and chemicals.

An ESOMAR-certified research organization, FMI provides custom and syndicated market reports and consulting services, supporting both Fortune 1,000 companies and SMEs. Its team of 300+ experienced analysts ensures credible, data-driven insights to help clients navigate global markets and identify growth opportunities.

For Press & Corporate Inquiries

Rahul Singh

AVP - Marketing and Growth Strategy

Future Market Insights, Inc.

+91 8600020075

For Sales - [email protected]

For Media - [email protected]

For web - https://www.futuremarketinsights.com/

SOURCE: Future Market Insights, Inc.

Information contained on this page is provided by an independent third-party content provider. XPRMedia and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact [email protected]